073

This document was uploaded by user and they confirmed that they have the permission to share it. If you are author or own the copyright of this book, please report to us by using this DMCA report form. Report DMCA

Overview

Download & View 073 as PDF for free.

More details

- Words: 3,540

- Pages:

Temperature,pressure measurementssolve column operatingproblems Scott W. Golden

R

efinery process engineers use computer modeling to design, monitor, operate, and troubleshoot refinery units. Basic chemical engineering princiwith these ples, coupled

ProcessConsulting ServicesInc.

high-technology tools, offer the engineer opportunities to identify and fix process unit problems. Pressure, temperature, and composition profiles are fundamental process meaFlq

Grapevine, Tex.

surements. But these tools that identify design and operating lems are often lost the more sophisticated tech tools. The details of three

simple system probamong high-

tions will show how these basic chemical engineering tools can be used to identify and solve operating problems in refinery distillation columns.

opera-

1

Fig. 2

Jet fuel

Reprinted

from the December 25, 1995 edition of OIL Copyright 1995 by PennWell

& GAS JOURNAL

OG

TECHNOLOGY I

Fig 3

Fig 4

0

ight cycle oil PA

+=Debutani*er

Normally no flow (Balance line)

1

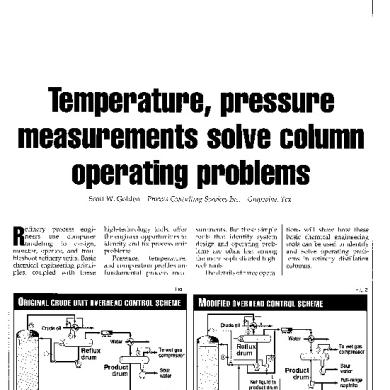

Case 1: Crude overhead Many atmospheric-pressure crude units have twodrum overhead systems.’ These systems are designed to improve unit energy efficiency by recovering some of the enthalpy from the column overhead vapor. Although these systems improve energy efficiency, they can cause corrosion and operating problems.* Fig. 1 shows a schematic of an overhead system that uses a hot reflux drum and a cold product drum. The product drum makes full-range naphtha, which the refiner uses as reformer feed. The first column side draw is jet fuel with a maximum 10% distillation specification of 400” F. The unit was designed to maximize naphtha yield while meeting the jet fuel front-end specification. Historically, however, the unit had been difficult to operate. It experienced corrosion, and product quality was difficult to control.

Control problems The operating objectives of this system are: l To control reflux-drum temperature at 280” F. minimum l To produce naphtha with a maximum D86 distillation 98 vol % point of 395” F.

Debutanizer

feed

l To produce jet fuel with a maximum 10 ~01% point of 400” F. It was not possible to meet all the control objectives using the design shown in Fig. 1. The refiner could meet either the reflux-drum temperature or the product distillation specifications, but not all the objectives. The system was operated to maintain the hot reflux drum at a minimum temperature of 280” F. to avoid corrosion in the crude-oil/overhead-vapor exchanger. Operators had determined that, by varying the reflux drum pressure from 11 to 18 psig, the control objectives could be met. Although column pressure is a novel independent variable for adjusting product composition in an atmospheric crude column and may not be optimum, it can be made to work. The operators should be given considerable credit for making an inherently unworkable system meet the product quality objectives and the reflux drum target temperature. Despite this success, the operating pressure of an atmospheric crude unit should not be used as an independent variable. Although it is theoretically possible to meet the control objectives in this manner, it is undesirable for several rea-

“F.

ight cycle oil PA

bottoms

Debutanizer

Temperature,

ed.

sons, including: column l Minimizing pressure reduces atmospheric residue yield. l Operating experience on this column showed that temperatures less than 280” F. in the reflux drum caused severe operating problems. Salt deposition resulted in corrosion in the heat exchanger and fouling of the column’s top trays.

Original design The system did not work as intended. As they always do, the operators had found a way around the problem. They used pressure, temperature, and composition to meet the control objectives. Following their example, pressure, temperature, and composition will be used to analyze the problem. Over time, crude oil composition changes. For each crude blend, there are differing amounts of naphtha, light straight run, and light ends in the feed. For a given crude oil composition, the operating conditions in the overhead are essentially fixed by the crude composition and column heat balance. For this unit, avoiding corrosion and salt deposition was the primary control objective. The reflux drum was operated at 280” F. This temperature was maintained by bypassing a portion of the

bottoms

Debutanizer

feed

crude around the crude/overhead-vapor heat exchanger. For a given composition of overhead from the column, the quantity of material condensed at 280” F. and 15 psig is fixed. The column reflux rate is set by returning all the reflux-drum liquid to the column. The quantity of reflux to the column determines the composition of the column overhead vapor. If, when operating this column, the overhead did not meet specification (naphtha end point), the operators would change the pressure in the reflux drum. They were able to meet the control objectives, although this was achieved at the expense of varying atmospheric residue production. Problems in refinery multidraw distillation columns are best analyzed using material balance envelopes. A simplification of the material balance on the overhead system is: Column overhead vapor = Reflux + Refluxdrum vapor. Assuming a given crude and a fixed jet fuel/diesel separation: Reflux-drum vapor = Naphtha product + Light ends. In addition, Naphtha + Jet fuel = Constant. If the reflux-drum temperature is maintained, varia-

TECH IOLOGY Fig

5

28

Flash drum vapors 4

tions in reflux-drum pressure change the quantity of material condensed in the reflux drum. This, in turn, changes the quantities of naphtha and jet fuel produced. A decrease in the quantity of naphtha and an increase in the quantity of jet fuel cause a reduction in, respectively, the naphtha end point and the jet fuel 10 vol % point. The operators were intuitively applying basic chemical engineering theory to operate this column. Unfortunately, however, sophisticated process models have gained such widespread acceptance that basic theory often is considered mundane and boring. Basic distillation theory defines the problem as a multicomponent flash.’ Pressure, temperature, and composition, in conjunction with the aforementioned material-balance equations, simplify the problem. It must be remembered that pressure and temperature determine composition. Once two variables are fixed, the third is also fixed, assuming the fluid is at equilibrium.

Modified flow scheme The principles of pressure, temperature, and composition can be used to solve the problem in this unit. Fig. 2 shows a modified process

Flash drum vapors -b

flow scheme that has been used effectively on two-drum overhead systems. These units process a wide variety of crude oils with naphtha yields ranging from 4 to 20% of crude. The system shown in Fig. 2 separates control of the naphtha and jet fuel yields from operation of the reflux drum. The control objectives are the same as for the flow scheme in Fig. 1. The method of meeting these objectives, however, differs. In Fig. 2, pressure changes are not needed to meet the control objectives. The column operating pressure thus can be maintained at minimum levels set by column hydraulic loading. The changes in the process flow scheme shown in Fig. 2 affect the overhead system material balance. The new material balance equations are: l Column overhead vapor = Reflux + Refluxdrum vapor + Net liquid to product drum l Reflux-drum vapor = Naphtha product + Light ends + Refluxed liquid from product drum l Naphtha + Jet fuel = Constant (assuming a given crude and fixed jet fuel/diesel separation). The system now operates in the following manner: l Net liquid from the

-..2LL 30

reflux drum to the product drum is always maintained. Crude composition changes will be reflected in the quantity of this stream; nevertheless, it will always be maintained, irrespective of other operating conditions. l Refluxed liquid from the product drum will be varied from zero to some positive value. When there is net liquid in the reflux drum as a result of a particular crude oil composition, the flow rate from the product drum will be zero. The position indicator on the product-drum valve is used to indicate flow qualitutively. When the net liquid from the reflux drum has no flow, the flow of the product-drum reflux stream will be positive. This system separates the inherent link between the pressure and temperature of the reflux drum and the naphtha and jet fuel compositions. The naphtha and jet fuel material balance can be varied while avoiding refluxdrum temperatures that cause product specification problems. The size of the two lines added to the system is a function of variations in crude oil blends. Advanced control schemes can be applied easily to the process flow scheme shown in Fig. 2.

pumparound 553

AGO draw

Case 2: De-C2reboiler The de-ethanizer, or stripper, in a fluid catalytic cracking (FCC) unit removes C2 and H,S from the debutanizer feed. The C, bottom-product specification is a function of the downstream unit’s processing tolerance for C2s. De-ethanizer column reboiler systems often use some type of series or parallel scheme to recover low-temperature heat.“’ These columns are inherently difficult to control because the C, content cannot be inferred accurately from column temperature. Small changes in columntray or reboiler-outlet temperature result in large changes in C, content. Thus, de-ethanizer columns normally are operated using higher “boil-up” than necessary, because of the difficulty of controlling CZs.“’ Fig. 3 is a flow diagram of a typical series-reboiler system for a de-ethanizer. The system comprises a thermosyphon in series with a kettle reboiler. The thermosyphon uses a low-temperature heat source from either the debutanizer or the FCC main fractionator. The kettle generally uses light cycle oil pumparound heat from the main fractionator. (Typical heat duty is two thirds low-temperature heat

TECHNOLOGY and one third high-temperature heat.) In principle, all the liquid leaving the bottom tray (total draw) flows to the thermosyphon reboiler. The vapor and liquid from the thermosyphon flow to the kettle. The thermosyphon and kettle reboiler represent more than one theoretical stage of separation. An alternate scheme separating the thermosyphon and kettle reboiler will yield closer to two theoretical stages. The liquid level in the kettle and the column bottoms is maintained near the midpoint of the tube bundle overflow baffle on the reboiler. The kettle reboiler has a balance line back to the column. The balance line often is cold to the touch because there is little or no flow in it. The liquid level indicator should always be placed on the reboiler because the liquid level in the column is higher as a result of the pressure drop in the outlet line from the kettle reboiler. This pressure drop is normally low. On one FCC deethanizer, however, a high pressure drop in the vapor line, coupled with use of a liquid-level indicator on the column rather than the reboiler, resulted in a flooded kettle reboiler. Depending on the exchanger bundle design, baffles typically are only 3 or 4 ft tall. A large tube-bundle diameter coupled with a short tube length is preferred for this service because it increases baffle height.

Bottom composition A 55,000 b/d FCC unit was having difficulty controlling the C, content in the bottoms product. Increasing heat input did not improve the C, content enough to meet the LPG specification. The stripper heat input had been increased sufficiently to flood the column. The liquid inventory in the column “dumped” intermittently into the high-pressure receiver via the column overhead vapor line.

Because the high-pressure receiver liquid is stripper feed, a giant recycle loop is created. Some operators call this recycling “snowballing.” Large build-up of C2s can occur in this type of system because of low temperatures.

Columnprofiles Composition and temperature data were gathered around the reboiler system to determine the cause of the C, composition problem. Fig. 4 shows the temperature data taken from the unit. There was flow in the balance line, and its temperature was slightly more than that of the liquid on the bottom tray. On a more basic level, the line was hot to the touch, which indicates flow from the column through the balance line. Temperature measurements were taken at various points in the system. These values were: l Bottom tray, 190” F. l Balance line, 200” F. l Reboiler liquid outlet, 263” F. l Debutanizer feed, 255” F. Computer simulation models allow the engineer to generate changes in composition profile, as do McCabeThiele and Hengstebeck diagrams.” The difference between these types of diagrams and computer models is that the models are much faster. In this de-eth%nizer, there is a very large change in temperature and composition across the bottom stages. If the reboiler system is operating properly, the liquid flowing from the bottom tray will have 3.5-4.5 times more C2s than the bottom product. Various streams were measured for C, content. The results were: l Bottom tray liquid, 0.20 mole Y0 l Balance line liquid, 0.17 mole % l Reboiler outlet, 0.05 mole % l Column bottoms product, 0.08 mole %. The high C2 content in the column bottoms was caused

by problems in the reboiler system’s hydraulics. The unit had been designed for less than 40,000 b/d capacity. Unit throughput and conversion were higher than intended. When the unit charge and the quantity of debutanizer feed were increased, the reboiler system was unable to handle all the flow from the bottom tray. Some of the bottom-tray liquid, therefore, was bypassing the reboiler, causing high C2 content material to be mixed with reboiler outlet liquid. There were two causes of the hydraulic limitations: l Improper line sizes on the kettle vapor-return line l Too high a system pressure-drop from the bottomtray liquid draw to the kettle. These limitations result in liquid bypassing the reboiler system. In this case, temperature and composition profiles in the reboiler system identified these two culprits. The operating problem was solved by eliminating the hydraulic bottlenecks.

Case 3: Crude column An atmospheric crude colmodified to umn was increase the capacity of its diesel pumparound section because crude charge capacity had been increased and the diesel pumparound section was causing a bottleneck. During start-up, the column had experienced operating problems, and a pressure surge was recorded. Fig. 5 is a flow diagram of the diesel/atmospheric gas oil (AGO) section of the column, as designed.

Pumparound problem After the modification, the diesel pumparound pumps were cavitating and no liquid could be withdrawn from Tray 28. The column was gamma-scanned, but no conclusions were drawn. The gamma scan was interpreted to indicate that the trays were in place. The column draw had to be modified, however, to allow heat

removal from the diesel pumparound. The column could not be operated as designed. The diesel draw on Tray 24 had been used to draw both the product and the column internal reflux. But the operators found a way to convert the operation from a pumparound to a pumpdown. This was an innovative solution to a problem that could have caused a shutdown. Fig. 6 is a diagram of the modified flow scheme (the diesel pumpdown pumps are not shown). Computer modeling of the modified flow scheme was conducted in parallel with the gamma scan. Because neither the gamma scans nor the computer models identified the problem, some basic plant data were gathered and evaluated.

Columnprofiles Atmospheric crude distillation columns fractionate the feed components into products, based on downstream unit feed specifications and refinery product specifications. Temperature, pressure, and composition changes are inherent to the distillation process. Proficiency with computer models and overreliance on gamma scanning have displaced the idea of looking to plant data for solutions to processing problems. Pressure, temperature, and composition profiles (variations within a given system) are often overlooked as powerful troubleshooting tools. Although the tools available to today’s process engineer are wonderful, basic distillation principles should not be overlooked: l Liquid is heaviest at the bottom of a column and becomes lighter as it moves up the column. In an atmospheric crude column, the 50% point can be used to measure where a product is withdrawn from the column. l Column temperature decreases from bottom to top. The change per tray is a function of the individual

TECHNOLOGY

r

Table

I

Vol % distilled

1

Temperatures, “F Diesel AGO

5:

579 542

648 598

z: 100

627 649 688

749 711 817

ments at low cost. On this column, pressure, temperature, and composition data were collected in the diesel/AGO section of the column. (When evaluating trayed atmospheric distillation column operations, profiles of pressure, temperature, and composition should always be gathered.)

Pressure

process. Proper changes ir tray temperature can bc determined using a comput er model. l In a trayed column, the pressure drop per tray varie: between 0.075 psi and 0.1: psi when the trays are func tioning properly. Although these are simple aspects that may be easil) understood, the importance 2f their application in trou2leshooting and monitoring distillation columns cannol 3e overstated. Gamma scanning is i sophisticated too1 thai requires proper execution. I’ often is performed incorrect ly, resulting in many incor rect interpretations. (Thl author has been told severa times that a column is flood ed, when the gamma seal was mistakenly detectin! downcomers.) These sophisticated tool require highly trained per sonnel to use them correctly By contrast, temperature pressure, and compositior data can be gathered quickl! using simple, reliable instru

One symptom of the operating problem in this tower was the inability to draw diesel pumparound liquid. The diesel product draw was at Tray 24 and the diesel pumparound draw, at Tray 28. The inability to draw liquid from an active tray means the tray is either “weeping“ or mechanically damaged such that liquid is not allowed to reach the draw sump. Pressure drop was measured between the available pressure taps in the column. The following values were measured simultaneously using two calibrated gauges: l Trays 28-29, 0.1 psi l Trays 24-29, 0.2 psi. These low pressure drops indicate tray damage.

Temperature Following the pressure measurements, the column temperature profile was evaluated. Trays 24-27 had thermowells. The draw-tray temperatures were measured, and the resulting temperature profile is shown in Fig. 6. Temperatures at the diesel and AGO draw trays were, respectively, 562” F. and 553” F. It is important to note that the diesel draw temperature was higher than that of the AGO draw, even though the diesel draw tray was six trays

I

higher than the AGO draw. (The AGO product draw should be hotter than the diesel because AGO is higher-boiling-range material.)

Composition During the temperature and pressure profile measurements, distillation analyses were performed on the diesel and AGO products (Table 1). As expected, the distillation showed that the AGO had a 50% boiling point that was 56” F. higher than diesel’s, The profiles also indicated three unexpected results: l The AGO draw is colder than the diesel draw. l The column temperature profile does not change materially from Tray 24 to Tray 27. l The pressure drop on the diesel pumparound trays is very low. The only reasonable interpretation of these results is that the diesel pumparound trays have been damaged. Although the subcooled pumpdown reflux is having some contact with the vapor, the AGO product equilibrium temperature is not being reached.

References I. Bannon, R.P., and Marple, S., Jr., “Heat Recovery in liydrocarbon Systems,” Chem. Eng. Prog., July 1978, pp. 41-45. !. Lieberman, N.P., “Four steps solve crude-tower overhead corrosion problems,” OCJ, July 5, 1993, pp. 47-50. 3. Kern, D.Q., Process Heat Transfer, McGraw Hill, 1950, p. 335. t. Martin, G.R., and Sloley, A.W., “Effectively Design and Simulate Thermosyphon Reboiler Systems, Part 1,” Hydrocarbon Processing, June 1995, pp. lO10. i. Martin, G.R., and Sloley, A.W., “Effectively Design and Simulate Thermosyphon Reboiler Systems, Part 2,” Hydrocarbon Processing, July 1995, pp. 67.78. 6. Fleming, B., Sloley, A.W., and Golden, S.W., “Heat Integratmg Fluid Catalytic Cracking Unit Fractmnation Systems,” Paper lY5b, AlChE fall meeting, Nov. 11, 1994, St. Louis. 7. Sk&y, A.W., and Martin, G.R., “Process Modelq for Control System Design and Analysts,” Proceedings from the Conference on Modeling, Simulation, and Control in the Process Industry, I’apf2r 208-007, Ottawa, Ont., May 25-27, pp. 107-l 5. 8. Kister, H.Z., Distillation Design, McGraw Hill, 1992, pp. 67-71.

1

BOOKS Natural Gas In The World-1995 Survey, published by Cedigaz, 1 li 4 avenue de Bois-Preau, BP 311, 92506 Rueil Malmaison Cedex, France. 140 pp., $1,160. This annual statistical survey from Cedigaz contains the latest data on the reserves, production, international trade, consumption, and natural gas prices in 1993 and 1994. The 199596 outlook is also developed. The study includes gas statistics for 96 countries with detailed commentaries for the major countries.

Reformulated Gasoline: Lessons from America, by Adam Seymour. Published by Oxford Institute for Energy Studies, 57 Woodstock Rd., Oxford OX2 6FA, England. 90 pp., El4 in U.K., El6 overseas. The book examines in detail the U.S. reformulated gasoline program which came into effect Jan. 1, 1995. The study analyses the problems the program has encountered in its first crucial months. In contrast to experience in previous fuel quality programs, says the author, widely expected problems, of implementation have not yet emerged.

A Year on the (H)Edge: Integrating Physical and Paper Fundamentals for Insight on the Oil Markets in 1994and 1995, by Edward N. Krnpels and Sarah A. Emerson. Publisked by Hobijn French Publishing Co., P.O. Box 34736, Washington, D.C. 20043. 160 pp. no price available. This book outlines the authors’ new approach to oil price forecasting, which integrates fundamental analysis of the physical markets with a full accounting for the role of volatile financial markets.

R

efinery process engineers use computer modeling to design, monitor, operate, and troubleshoot refinery units. Basic chemical engineering princiwith these ples, coupled

ProcessConsulting ServicesInc.

high-technology tools, offer the engineer opportunities to identify and fix process unit problems. Pressure, temperature, and composition profiles are fundamental process meaFlq

Grapevine, Tex.

surements. But these tools that identify design and operating lems are often lost the more sophisticated tech tools. The details of three

simple system probamong high-

tions will show how these basic chemical engineering tools can be used to identify and solve operating problems in refinery distillation columns.

opera-

1

Fig. 2

Jet fuel

Reprinted

from the December 25, 1995 edition of OIL Copyright 1995 by PennWell

& GAS JOURNAL

OG

TECHNOLOGY I

Fig 3

Fig 4

0

ight cycle oil PA

+=Debutani*er

Normally no flow (Balance line)

1

Case 1: Crude overhead Many atmospheric-pressure crude units have twodrum overhead systems.’ These systems are designed to improve unit energy efficiency by recovering some of the enthalpy from the column overhead vapor. Although these systems improve energy efficiency, they can cause corrosion and operating problems.* Fig. 1 shows a schematic of an overhead system that uses a hot reflux drum and a cold product drum. The product drum makes full-range naphtha, which the refiner uses as reformer feed. The first column side draw is jet fuel with a maximum 10% distillation specification of 400” F. The unit was designed to maximize naphtha yield while meeting the jet fuel front-end specification. Historically, however, the unit had been difficult to operate. It experienced corrosion, and product quality was difficult to control.

Control problems The operating objectives of this system are: l To control reflux-drum temperature at 280” F. minimum l To produce naphtha with a maximum D86 distillation 98 vol % point of 395” F.

Debutanizer

feed

l To produce jet fuel with a maximum 10 ~01% point of 400” F. It was not possible to meet all the control objectives using the design shown in Fig. 1. The refiner could meet either the reflux-drum temperature or the product distillation specifications, but not all the objectives. The system was operated to maintain the hot reflux drum at a minimum temperature of 280” F. to avoid corrosion in the crude-oil/overhead-vapor exchanger. Operators had determined that, by varying the reflux drum pressure from 11 to 18 psig, the control objectives could be met. Although column pressure is a novel independent variable for adjusting product composition in an atmospheric crude column and may not be optimum, it can be made to work. The operators should be given considerable credit for making an inherently unworkable system meet the product quality objectives and the reflux drum target temperature. Despite this success, the operating pressure of an atmospheric crude unit should not be used as an independent variable. Although it is theoretically possible to meet the control objectives in this manner, it is undesirable for several rea-

“F.

ight cycle oil PA

bottoms

Debutanizer

Temperature,

ed.

sons, including: column l Minimizing pressure reduces atmospheric residue yield. l Operating experience on this column showed that temperatures less than 280” F. in the reflux drum caused severe operating problems. Salt deposition resulted in corrosion in the heat exchanger and fouling of the column’s top trays.

Original design The system did not work as intended. As they always do, the operators had found a way around the problem. They used pressure, temperature, and composition to meet the control objectives. Following their example, pressure, temperature, and composition will be used to analyze the problem. Over time, crude oil composition changes. For each crude blend, there are differing amounts of naphtha, light straight run, and light ends in the feed. For a given crude oil composition, the operating conditions in the overhead are essentially fixed by the crude composition and column heat balance. For this unit, avoiding corrosion and salt deposition was the primary control objective. The reflux drum was operated at 280” F. This temperature was maintained by bypassing a portion of the

bottoms

Debutanizer

feed

crude around the crude/overhead-vapor heat exchanger. For a given composition of overhead from the column, the quantity of material condensed at 280” F. and 15 psig is fixed. The column reflux rate is set by returning all the reflux-drum liquid to the column. The quantity of reflux to the column determines the composition of the column overhead vapor. If, when operating this column, the overhead did not meet specification (naphtha end point), the operators would change the pressure in the reflux drum. They were able to meet the control objectives, although this was achieved at the expense of varying atmospheric residue production. Problems in refinery multidraw distillation columns are best analyzed using material balance envelopes. A simplification of the material balance on the overhead system is: Column overhead vapor = Reflux + Refluxdrum vapor. Assuming a given crude and a fixed jet fuel/diesel separation: Reflux-drum vapor = Naphtha product + Light ends. In addition, Naphtha + Jet fuel = Constant. If the reflux-drum temperature is maintained, varia-

TECH IOLOGY Fig

5

28

Flash drum vapors 4

tions in reflux-drum pressure change the quantity of material condensed in the reflux drum. This, in turn, changes the quantities of naphtha and jet fuel produced. A decrease in the quantity of naphtha and an increase in the quantity of jet fuel cause a reduction in, respectively, the naphtha end point and the jet fuel 10 vol % point. The operators were intuitively applying basic chemical engineering theory to operate this column. Unfortunately, however, sophisticated process models have gained such widespread acceptance that basic theory often is considered mundane and boring. Basic distillation theory defines the problem as a multicomponent flash.’ Pressure, temperature, and composition, in conjunction with the aforementioned material-balance equations, simplify the problem. It must be remembered that pressure and temperature determine composition. Once two variables are fixed, the third is also fixed, assuming the fluid is at equilibrium.

Modified flow scheme The principles of pressure, temperature, and composition can be used to solve the problem in this unit. Fig. 2 shows a modified process

Flash drum vapors -b

flow scheme that has been used effectively on two-drum overhead systems. These units process a wide variety of crude oils with naphtha yields ranging from 4 to 20% of crude. The system shown in Fig. 2 separates control of the naphtha and jet fuel yields from operation of the reflux drum. The control objectives are the same as for the flow scheme in Fig. 1. The method of meeting these objectives, however, differs. In Fig. 2, pressure changes are not needed to meet the control objectives. The column operating pressure thus can be maintained at minimum levels set by column hydraulic loading. The changes in the process flow scheme shown in Fig. 2 affect the overhead system material balance. The new material balance equations are: l Column overhead vapor = Reflux + Refluxdrum vapor + Net liquid to product drum l Reflux-drum vapor = Naphtha product + Light ends + Refluxed liquid from product drum l Naphtha + Jet fuel = Constant (assuming a given crude and fixed jet fuel/diesel separation). The system now operates in the following manner: l Net liquid from the

-..2LL 30

reflux drum to the product drum is always maintained. Crude composition changes will be reflected in the quantity of this stream; nevertheless, it will always be maintained, irrespective of other operating conditions. l Refluxed liquid from the product drum will be varied from zero to some positive value. When there is net liquid in the reflux drum as a result of a particular crude oil composition, the flow rate from the product drum will be zero. The position indicator on the product-drum valve is used to indicate flow qualitutively. When the net liquid from the reflux drum has no flow, the flow of the product-drum reflux stream will be positive. This system separates the inherent link between the pressure and temperature of the reflux drum and the naphtha and jet fuel compositions. The naphtha and jet fuel material balance can be varied while avoiding refluxdrum temperatures that cause product specification problems. The size of the two lines added to the system is a function of variations in crude oil blends. Advanced control schemes can be applied easily to the process flow scheme shown in Fig. 2.

pumparound 553

AGO draw

Case 2: De-C2reboiler The de-ethanizer, or stripper, in a fluid catalytic cracking (FCC) unit removes C2 and H,S from the debutanizer feed. The C, bottom-product specification is a function of the downstream unit’s processing tolerance for C2s. De-ethanizer column reboiler systems often use some type of series or parallel scheme to recover low-temperature heat.“’ These columns are inherently difficult to control because the C, content cannot be inferred accurately from column temperature. Small changes in columntray or reboiler-outlet temperature result in large changes in C, content. Thus, de-ethanizer columns normally are operated using higher “boil-up” than necessary, because of the difficulty of controlling CZs.“’ Fig. 3 is a flow diagram of a typical series-reboiler system for a de-ethanizer. The system comprises a thermosyphon in series with a kettle reboiler. The thermosyphon uses a low-temperature heat source from either the debutanizer or the FCC main fractionator. The kettle generally uses light cycle oil pumparound heat from the main fractionator. (Typical heat duty is two thirds low-temperature heat

TECHNOLOGY and one third high-temperature heat.) In principle, all the liquid leaving the bottom tray (total draw) flows to the thermosyphon reboiler. The vapor and liquid from the thermosyphon flow to the kettle. The thermosyphon and kettle reboiler represent more than one theoretical stage of separation. An alternate scheme separating the thermosyphon and kettle reboiler will yield closer to two theoretical stages. The liquid level in the kettle and the column bottoms is maintained near the midpoint of the tube bundle overflow baffle on the reboiler. The kettle reboiler has a balance line back to the column. The balance line often is cold to the touch because there is little or no flow in it. The liquid level indicator should always be placed on the reboiler because the liquid level in the column is higher as a result of the pressure drop in the outlet line from the kettle reboiler. This pressure drop is normally low. On one FCC deethanizer, however, a high pressure drop in the vapor line, coupled with use of a liquid-level indicator on the column rather than the reboiler, resulted in a flooded kettle reboiler. Depending on the exchanger bundle design, baffles typically are only 3 or 4 ft tall. A large tube-bundle diameter coupled with a short tube length is preferred for this service because it increases baffle height.

Bottom composition A 55,000 b/d FCC unit was having difficulty controlling the C, content in the bottoms product. Increasing heat input did not improve the C, content enough to meet the LPG specification. The stripper heat input had been increased sufficiently to flood the column. The liquid inventory in the column “dumped” intermittently into the high-pressure receiver via the column overhead vapor line.

Because the high-pressure receiver liquid is stripper feed, a giant recycle loop is created. Some operators call this recycling “snowballing.” Large build-up of C2s can occur in this type of system because of low temperatures.

Columnprofiles Composition and temperature data were gathered around the reboiler system to determine the cause of the C, composition problem. Fig. 4 shows the temperature data taken from the unit. There was flow in the balance line, and its temperature was slightly more than that of the liquid on the bottom tray. On a more basic level, the line was hot to the touch, which indicates flow from the column through the balance line. Temperature measurements were taken at various points in the system. These values were: l Bottom tray, 190” F. l Balance line, 200” F. l Reboiler liquid outlet, 263” F. l Debutanizer feed, 255” F. Computer simulation models allow the engineer to generate changes in composition profile, as do McCabeThiele and Hengstebeck diagrams.” The difference between these types of diagrams and computer models is that the models are much faster. In this de-eth%nizer, there is a very large change in temperature and composition across the bottom stages. If the reboiler system is operating properly, the liquid flowing from the bottom tray will have 3.5-4.5 times more C2s than the bottom product. Various streams were measured for C, content. The results were: l Bottom tray liquid, 0.20 mole Y0 l Balance line liquid, 0.17 mole % l Reboiler outlet, 0.05 mole % l Column bottoms product, 0.08 mole %. The high C2 content in the column bottoms was caused

by problems in the reboiler system’s hydraulics. The unit had been designed for less than 40,000 b/d capacity. Unit throughput and conversion were higher than intended. When the unit charge and the quantity of debutanizer feed were increased, the reboiler system was unable to handle all the flow from the bottom tray. Some of the bottom-tray liquid, therefore, was bypassing the reboiler, causing high C2 content material to be mixed with reboiler outlet liquid. There were two causes of the hydraulic limitations: l Improper line sizes on the kettle vapor-return line l Too high a system pressure-drop from the bottomtray liquid draw to the kettle. These limitations result in liquid bypassing the reboiler system. In this case, temperature and composition profiles in the reboiler system identified these two culprits. The operating problem was solved by eliminating the hydraulic bottlenecks.

Case 3: Crude column An atmospheric crude colmodified to umn was increase the capacity of its diesel pumparound section because crude charge capacity had been increased and the diesel pumparound section was causing a bottleneck. During start-up, the column had experienced operating problems, and a pressure surge was recorded. Fig. 5 is a flow diagram of the diesel/atmospheric gas oil (AGO) section of the column, as designed.

Pumparound problem After the modification, the diesel pumparound pumps were cavitating and no liquid could be withdrawn from Tray 28. The column was gamma-scanned, but no conclusions were drawn. The gamma scan was interpreted to indicate that the trays were in place. The column draw had to be modified, however, to allow heat

removal from the diesel pumparound. The column could not be operated as designed. The diesel draw on Tray 24 had been used to draw both the product and the column internal reflux. But the operators found a way to convert the operation from a pumparound to a pumpdown. This was an innovative solution to a problem that could have caused a shutdown. Fig. 6 is a diagram of the modified flow scheme (the diesel pumpdown pumps are not shown). Computer modeling of the modified flow scheme was conducted in parallel with the gamma scan. Because neither the gamma scans nor the computer models identified the problem, some basic plant data were gathered and evaluated.

Columnprofiles Atmospheric crude distillation columns fractionate the feed components into products, based on downstream unit feed specifications and refinery product specifications. Temperature, pressure, and composition changes are inherent to the distillation process. Proficiency with computer models and overreliance on gamma scanning have displaced the idea of looking to plant data for solutions to processing problems. Pressure, temperature, and composition profiles (variations within a given system) are often overlooked as powerful troubleshooting tools. Although the tools available to today’s process engineer are wonderful, basic distillation principles should not be overlooked: l Liquid is heaviest at the bottom of a column and becomes lighter as it moves up the column. In an atmospheric crude column, the 50% point can be used to measure where a product is withdrawn from the column. l Column temperature decreases from bottom to top. The change per tray is a function of the individual

TECHNOLOGY

r

Table

I

Vol % distilled

1

Temperatures, “F Diesel AGO

5:

579 542

648 598

z: 100

627 649 688

749 711 817

ments at low cost. On this column, pressure, temperature, and composition data were collected in the diesel/AGO section of the column. (When evaluating trayed atmospheric distillation column operations, profiles of pressure, temperature, and composition should always be gathered.)

Pressure

process. Proper changes ir tray temperature can bc determined using a comput er model. l In a trayed column, the pressure drop per tray varie: between 0.075 psi and 0.1: psi when the trays are func tioning properly. Although these are simple aspects that may be easil) understood, the importance 2f their application in trou2leshooting and monitoring distillation columns cannol 3e overstated. Gamma scanning is i sophisticated too1 thai requires proper execution. I’ often is performed incorrect ly, resulting in many incor rect interpretations. (Thl author has been told severa times that a column is flood ed, when the gamma seal was mistakenly detectin! downcomers.) These sophisticated tool require highly trained per sonnel to use them correctly By contrast, temperature pressure, and compositior data can be gathered quickl! using simple, reliable instru

One symptom of the operating problem in this tower was the inability to draw diesel pumparound liquid. The diesel product draw was at Tray 24 and the diesel pumparound draw, at Tray 28. The inability to draw liquid from an active tray means the tray is either “weeping“ or mechanically damaged such that liquid is not allowed to reach the draw sump. Pressure drop was measured between the available pressure taps in the column. The following values were measured simultaneously using two calibrated gauges: l Trays 28-29, 0.1 psi l Trays 24-29, 0.2 psi. These low pressure drops indicate tray damage.

Temperature Following the pressure measurements, the column temperature profile was evaluated. Trays 24-27 had thermowells. The draw-tray temperatures were measured, and the resulting temperature profile is shown in Fig. 6. Temperatures at the diesel and AGO draw trays were, respectively, 562” F. and 553” F. It is important to note that the diesel draw temperature was higher than that of the AGO draw, even though the diesel draw tray was six trays

I

higher than the AGO draw. (The AGO product draw should be hotter than the diesel because AGO is higher-boiling-range material.)

Composition During the temperature and pressure profile measurements, distillation analyses were performed on the diesel and AGO products (Table 1). As expected, the distillation showed that the AGO had a 50% boiling point that was 56” F. higher than diesel’s, The profiles also indicated three unexpected results: l The AGO draw is colder than the diesel draw. l The column temperature profile does not change materially from Tray 24 to Tray 27. l The pressure drop on the diesel pumparound trays is very low. The only reasonable interpretation of these results is that the diesel pumparound trays have been damaged. Although the subcooled pumpdown reflux is having some contact with the vapor, the AGO product equilibrium temperature is not being reached.

References I. Bannon, R.P., and Marple, S., Jr., “Heat Recovery in liydrocarbon Systems,” Chem. Eng. Prog., July 1978, pp. 41-45. !. Lieberman, N.P., “Four steps solve crude-tower overhead corrosion problems,” OCJ, July 5, 1993, pp. 47-50. 3. Kern, D.Q., Process Heat Transfer, McGraw Hill, 1950, p. 335. t. Martin, G.R., and Sloley, A.W., “Effectively Design and Simulate Thermosyphon Reboiler Systems, Part 1,” Hydrocarbon Processing, June 1995, pp. lO10. i. Martin, G.R., and Sloley, A.W., “Effectively Design and Simulate Thermosyphon Reboiler Systems, Part 2,” Hydrocarbon Processing, July 1995, pp. 67.78. 6. Fleming, B., Sloley, A.W., and Golden, S.W., “Heat Integratmg Fluid Catalytic Cracking Unit Fractmnation Systems,” Paper lY5b, AlChE fall meeting, Nov. 11, 1994, St. Louis. 7. Sk&y, A.W., and Martin, G.R., “Process Modelq for Control System Design and Analysts,” Proceedings from the Conference on Modeling, Simulation, and Control in the Process Industry, I’apf2r 208-007, Ottawa, Ont., May 25-27, pp. 107-l 5. 8. Kister, H.Z., Distillation Design, McGraw Hill, 1992, pp. 67-71.

1

BOOKS Natural Gas In The World-1995 Survey, published by Cedigaz, 1 li 4 avenue de Bois-Preau, BP 311, 92506 Rueil Malmaison Cedex, France. 140 pp., $1,160. This annual statistical survey from Cedigaz contains the latest data on the reserves, production, international trade, consumption, and natural gas prices in 1993 and 1994. The 199596 outlook is also developed. The study includes gas statistics for 96 countries with detailed commentaries for the major countries.

Reformulated Gasoline: Lessons from America, by Adam Seymour. Published by Oxford Institute for Energy Studies, 57 Woodstock Rd., Oxford OX2 6FA, England. 90 pp., El4 in U.K., El6 overseas. The book examines in detail the U.S. reformulated gasoline program which came into effect Jan. 1, 1995. The study analyses the problems the program has encountered in its first crucial months. In contrast to experience in previous fuel quality programs, says the author, widely expected problems, of implementation have not yet emerged.

A Year on the (H)Edge: Integrating Physical and Paper Fundamentals for Insight on the Oil Markets in 1994and 1995, by Edward N. Krnpels and Sarah A. Emerson. Publisked by Hobijn French Publishing Co., P.O. Box 34736, Washington, D.C. 20043. 160 pp. no price available. This book outlines the authors’ new approach to oil price forecasting, which integrates fundamental analysis of the physical markets with a full accounting for the role of volatile financial markets.